180 Degrees Out of Auto Distributor Gear Position Generated a No Start UPDATED

180 Degrees Out of Auto Distributor Gear Position Generated a No Start

Typical benefactor with distributor cap.

Likewise visible are mounting/drive shaft (bottom), vacuum advance unit (right) and capacitor (centre).

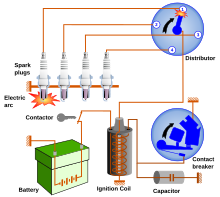

Motorcar ignition organization. Upper right is Benefactor.

A benefactor is an enclosed rotating shaft used in spark-ignition internal combustion engines that have mechanically timed ignition. The distributor's primary function is to road secondary, or high voltage, current from the ignition curl to the spark plugs in the correct firing club, and for the correct amount of time. Except in magneto systems and many modern calculator controlled engines that use crank angle/position sensors, the benefactor also houses a mechanical or anterior breaker switch to open up and shut the ignition coil's primary circuit.

The first reliable bombardment operated ignition was the Delco ignition system developed by Dayton Engineering Laboratories Co. (Delco) and introduced in the 1910 Cadillac Model 30. This ignition was adult by Charles Kettering and was considered a wonder in its twenty-four hours. Atwater Kent invented his Unisparker ignition organization almost this time in contest with the Delco arrangement.[1] Past the end of the 20th century mechanical ignitions were disappearing from automotive applications in favor of anterior or capacitive electronic ignitions fully controlled by engine command units (ECU), rather than directly timed to the engine's crankshaft speed.

Clarification [edit]

A distributor consists of a rotating arm or rotor within the benefactor cap, on peak of the distributor shaft, merely insulated from it and the body of the vehicle (ground). The distributor shaft is driven by a gear on the camshaft on most overhead valve engines, and attached directly to a camshaft on most overhead cam engines. (The distributor shaft may also bulldoze the oil pump.) The metallic part of the rotor contacts the high voltage cable from the ignition coil via a spring-loaded carbon castor on the underside of the benefactor cap. The metal part of the rotor arm passes close to (simply does not touch) the output contacts which connect via loftier tension leads to the spark plug of each cylinder. Equally the rotor spins within the distributor, electrical electric current is able to jump the small gaps created between the rotor arm and the contacts due to the high voltage created past the ignition coil.[2]

The distributor shaft has a cam that operates the contact breaker (as well called points). Opening the points causes a high induction voltage in the system's ignition curl.[2]

The distributor also houses the centrifugal advance unit: a prepare of hinged weights attached to the distributor shaft, that cause the breaker points mounting plate to slightly rotate and advance the spark timing with higher engine revolutions per minute (rpm). In add-on, the benefactor has a vacuum advance unit that advances the timing even further equally a office of the vacuum in the inlet manifold. Ordinarily at that place is also a capacitor attached to the distributor. The capacitor is connected parallel to the breaker points, to suppress sparking to foreclose excessive wear of the points.

Around the 1970s[ citation needed ] the primary breaker points were largely replaced with a Hall effect sensor or optical sensor. As this is a non-contacting device and the ignition coil is controlled past solid country electronics, a great corporeality of maintenance in bespeak aligning and replacement was eliminated. This too eliminates any problem with breaker follower or cam clothing, and past eliminating a side load information technology extends distributor shaft bearing life. The remaining secondary (high voltage) circuit stayed essentially the same, using an ignition coil and a rotary distributor.

Almost distributors used on electronically fuel injected engines lack vacuum and centrifugal accelerate units. On such distributors, the timing advance is controlled electronically by the engine computer. This allows more accurate control of ignition timing, as well as the power to alter timing based on factors other than engine speed and manifold vacuum (such every bit engine temperature). Additionally, eliminating vacuum and centrifugal advance results in a simpler and more reliable distributor.

Distributor cap [edit]

The benefactor cap is the cover that protects the distributor's internal parts and holds the contacts betwixt internal rotor and the spark plug wires.

The benefactor cap has one post for each cylinder, and in points ignition systems in that location is a cardinal post for the current from the ignition coil coming into the benefactor. At that place are some exceptions however, as some engines (many Alfa Romeo cars, some 1980s Nissans) accept 2 spark plugs per cylinder, and then there are two leads coming out of the distributor per cylinder. Another implementation is the wasted spark system, where a single contact serves two leads, merely in that case each lead connects one cylinder. In General Motors loftier free energy ignition (HEI) systems at that place is no central post and the ignition coil sits on superlative of the distributor. Some Toyota and Honda engines also have their gyre within the distributor cap. On the inside of the cap at that place is a concluding that corresponds to each post, and the plug terminals are arranged around the circumference of the cap co-ordinate to the firing society in order to send the secondary voltage to the proper spark plug at the right time.

The rotor is fastened to the top of the distributor shaft which is driven by the engine's camshaft and thus synchronized to information technology. Synchronization to the camshaft is required as the rotor must turn at exactly one-half the speed of the main crankshaft in the 4-stroke wheel. Often, the rotor and distributor are attached directly to the end of one of the (or the only) camshaft, at the reverse terminate to the timing drive belt. This rotor is pressed against a carbon brush on the centre terminal of the distributor cap which connects to the ignition coil. The rotor is constructed such that the middle tab is electrically connected to its outer edge and then the current coming in to the heart mail service travels through the carbon point to the outer edge of the rotor. As the camshaft rotates, the rotor spins and its outer border passes each of the internal plug terminals to burn down each spark plug in sequence.

Engines that use a mechanical distributor may fail if they run into deep puddles considering any water that gets onto the distributor can short out the electric current that should get through the spark plugs, rerouting it directly to the trunk of the vehicle. This in turn causes the engine to stop as the fuel is not ignited in the cylinders.[3] This trouble tin be fixed by removing the distributor'southward cap and drying the cap, cam, rotor and the contacts by wiping with tissue paper or a clean rag, by bravado hot air on them, or using a moisture deportation spray e.g. WD-forty or similar. Oil, dirt or other contaminants can cause similar problems, so the distributor should be kept make clean inside and outside to ensure reliable operation.[four] Some engines include a rubber o-band or gasket between the benefactor base of operations and cap to help prevent this trouble. The gasket is made of a textile like Viton or butyl for a tight seal in extreme temperatures and chemic environments.[five] This gasket should not be discarded when replacing the cap. Most distributor caps have the position of the number one cylinder's terminal molded into the plastic. By referencing a firing order diagram and knowing the direction the rotor turns, (which tin be seen by cranking the engine with the cap off) the spark plug wires can be correctly routed. Most distributor caps are designed so that they cannot be installed in the wrong position. Some older engine designs allow the cap to be installed in the wrong position by 180 degrees, all the same. The number 1 cylinder position on the cap should be noted before a cap is replaced.

The distributor cap is a prime example of a component that somewhen succumbs to heat and vibration. It is a relatively easy and inexpensive part to replace if its bakelite housing does non break or crack first. Carbon deposit accumulation or erosion of its metal terminals may likewise cause distributor-cap failure.

Equally information technology is mostly easy to remove and conduct off, the benefactor cap tin can be taken off as a means of theft prevention. Although not practical for everyday use, because it is essential for the starting and running of the engine, its removal thwarts whatsoever attempt at hot-wiring the vehicle.

-

Breaker arm with contact points at the left. The pivot is on the right and the cam follower is in the middle of the breaker arm.

-

Benefactor cap. At the center is a leap-loaded carbon button that touches the rotor. The number of contacts (in this example 4) is the same as the number of engine cylinders

-

Rotor. This rotates at the same speed as the camshaft, one one-half the speed of the crankshaft

-

Pinnacle of distributor with wires and terminals

-

Rotor contacts within benefactor cap

Directly and distributorless ignition [edit]

Mod engine designs have abased the loftier-voltage distributor and curl, instead performing the distribution function in the principal excursion electronically and applying the primary (low-voltage) pulse to individual coils for each spark plug, or one coil for each pair of companion cylinders in an engine (two coils for a four-cylinder, three coils for a vi-cylinder, 4 coils for an viii-cylinder, then on).

In traditional remote distributorless systems, the coils are mounted together in a transformer oil filled coil pack, or separate coils for each cylinder, which are secured in a specified identify in the engine compartment with wires to the spark plugs, similar to a distributor setup. General Motors, Ford, Chrysler, Hyundai, Subaru, Volkswagen and Toyota are among the automobile manufacturers known to accept used curl packs. Curl packs by Delco for utilize with General Motors engines permit removal of the individual coils in instance one should fail, but in well-nigh other remote distributorless coil pack setups, if a coil were to fail, replacement of the whole pack would be required to fix the trouble.

More recent layouts utilise a whorl located very most to each spark plug known as scroll-virtually-plugs, or directly on top of each spark plug known every bit direct ignition (DI) or coil-on-plug (COP). This design avoids the need to transmit very loftier voltages, which is often a source of trouble, especially in damp conditions.

Both direct and remote distributorless systems also permit finer levels of ignition control by the engine computer, which helps to increase power output, decrease fuel consumption and emissions, and implement features such equally cylinder deactivation. Spark plug wires, which demand routine replacement due to degradation, are likewise eliminated when the individual coils are mounted directly on top of each plug, since the loftier voltages and fields exist only over a very brusque distance from the coil to the plug.

Wasted spark [edit]

The distributor can be eliminated on four-stroke engines by using the wasted spark principle. An ignition pulse is delivered to two cylinders at the aforementioned time,chosen so that ane cylinder is in an exhaust stroke while the other is nearly to begin the power stroke. The spark in the cylinder on the exhaust phase is wasted. Each end of the ignition curl winding is connected to a spark plug and they fire in pairs.

A single-cylinder engine has but one spark plug and and then needs no distributor. Ignition systems on such engines may produce a wasted spark during the exhaust stroke.

See as well [edit]

- Saab Direct Ignition

- Timing mark

References [edit]

- ^ "Cadillac History | Kanter Motorcar Tales". kanter-car-tales.com . Retrieved 2016-02-12 .

- ^ a b "How the ignition arrangement works". How a Auto Works . Retrieved 2016-02-12 .

- ^ "Misfire from driving through "wave of h2o" likely result of moisture distributor cap — a trouble that'southward not costly to fix". Mail service and Courier . Retrieved 2016-02-12 .

- ^ mitmaks (2014-03-23), Cleaning benefactor cap , retrieved 2016-02-12

- ^ "Rubber Gaskets and Soft Gaskets - Mercer Gasket & Shim". Mercer Gasket & Shim . Retrieved 2016-02-12 .

External links [edit]

| | Expect up distributor in Wiktionary, the free dictionary. |

DOWNLOAD HERE

180 Degrees Out of Auto Distributor Gear Position Generated a No Start UPDATED

Posted by: kristinkinty1970.blogspot.com

Comments

Post a Comment